|

Pottery? O.K. Teapottery? Huh?

By Shona

Adhikari

IF tea is your favourite beverage,

then read on! This is an article about the designing and

the fine craftsmanship involved in the making of

innovative teapots — teapots that are unlike any

that one has ever seen. During a recent visit to

England’s Lake District, I stumbled purely by chance

on the Teapottery factory at Keswick.

Intrigued

by the name on the two-storeyed building, just off the

main street, I wandered in and was completely floored by

the ingenuity and imagination that had gone into

designing and shaping what were actually teapots! There

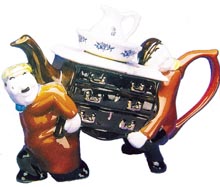

were pots shaped like pop-up toasters complete with

toasts, wash basins with gilded taps, bathtubs with

towels and soap, cameras, racing cars, pianos, suitcases,

stoves, fireplaces, dressers, armchairs — in short

anything that you can possibly think of! Intrigued

by the name on the two-storeyed building, just off the

main street, I wandered in and was completely floored by

the ingenuity and imagination that had gone into

designing and shaping what were actually teapots! There

were pots shaped like pop-up toasters complete with

toasts, wash basins with gilded taps, bathtubs with

towels and soap, cameras, racing cars, pianos, suitcases,

stoves, fireplaces, dressers, armchairs — in short

anything that you can possibly think of!

The larger, pots come

priced around £30, while the smaller ‘one-cup

wonders’ are about £18. Not cheap certainly, but a

great gift for anyone who has a passion for tea —

and from the business that Teapottery has managed to

generate, it is obvious that there are many tea-lovers in

the world. Production, is not large since each piece is

handcrafted, but a third of the teapots made are sent

abroad, on orders. The rest are sold through the

Teapottery shops at Keswick and Leyburn, and at

department stores, tea and coffee retailers, gift shops

and cookery shops in the UK.

The Teapottery story

began in 1967, when Judy Rance and Martin Bibby met at

Hornsey College of Art in London. Judy was taking a

course in fashion and textile design, while Martin was

studying ceramics. By 1978 they were itching to start

their own pottery, and they impetuously put all their

savings into buying a derelict farm at Swineside, in the

Yorkshire Dales. They named their venture ‘Swineside

Ceramics’, and took on their first employees, Karen

and Liz — who are still with them and are now joint

production managers, at the Teapottery factory at

Leyburn.

Swineside Ceramics

quickly developed a reputation for innovative designs of

various items, including a set of three teapots, each

shaped as a head sporting a distinctive hairdo. As orders

increased, more and more of the farm and its outbuildings

were renovated — until there were no derelict bits

left! In the quest for more space, and to avoid being

snowed in quite so often in winter, Swineside Ceramics

moved from the bleek moors into Leyburn, a bustling

market town in North Yorkshire.

By 1986, the teapots

were generating so much interest in the UK and abroad,

that Judy and Martin decided to concentrate exclusively

on them — thus Swineside Ceramics, became Swineside

Teapottery. Three years later production was transferred

to a new, purpose-built factory in Leyburn Business Park.

Since passersby insisted on having a look around, a

walkway was created, so that every step of production

could be seen, and a cup of tea was offered at the end at

the cosy showroom and shop, where the complete range

would be displayed.

The second Teapottery

factory at Keswick was opened as recently as 1995, so

that many visitors to the Lake District could watch and

learn about the process of making these innovative,

eccentric teapots. On the day I visited the workshop.

There were at least another 10 people wandering around

the place, and showing great interest in the details of

the history of tea pictorially represented on panels at

the entrance.

Inside the workshop, the

first process begins with a rather noisy machine called a

blunger. Rather like a giant food mixer, its job is to

blend solid clay with water, and is Teapottery’s

concessions to 20th Century technology. Next comes the

moulding section, where the clay is poured into plaster

moulds, which gradually absorb the moisture. Here we were

able to see moulds being opened and the slip-cast

components of the teapots-to-be, carefully taken out.

These are said to be as pliable as leather, and only too

easy to tear or damage.

Next comes the sponging

area, where each piece is checked and imperfections

carefully removed and sent on to the kiln for the first

firing. Next comes the decorating section and we saw a

highly skilled artist carefully decorating the current

batch of teapots, shaped like wooden chests. After

painting the pieces are glazed and then sent for the

second firing. Next comes the second round of decoration

the gold and silver tlustres are painted on by hand. And

after the third firing the piece is finally ready.

The showroom upstairs

has a wide range of most of the special Biddy designs

— every single design made is the combined effort of

this highly creative couple. While most of the people at

the showroom were only visiting, there was one customer

looking for a gift for her brother — who

particularly enjoyed his cuppa. It transpired that she

was able to find exactly the right pot, for another of

her brothers passions was cricket, and sure enough

Teapottery had this splendid teapot created specially for

cricket lovers — complete with cricket bat, ball and

wicket.

|